April 2021

KOHPA® – a new material for the future

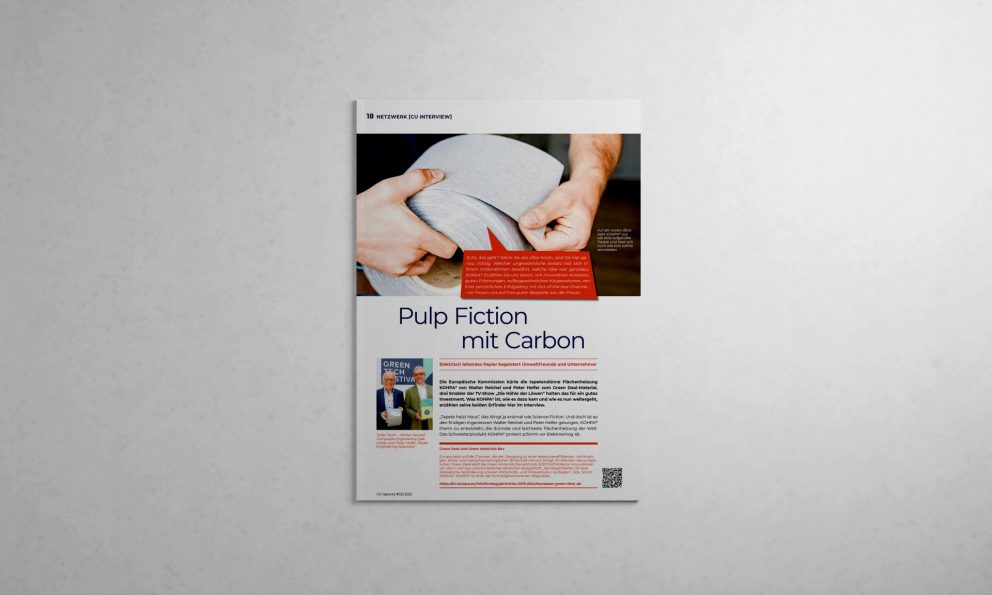

Through many years of research and industrial carbon fiber paper production, using different carbon contents, it was necessary to find an electrical reaction level that enables the project to generate surface heating that meets the practical conditions. Papers with different C-content exhibited different electrical resistance.

The overall investigations show that the electrical conductivity values change as a result of the smallest changes in the C content. During the industrial production of carbon fiber paper, this phenomenon requires extremely precise metering and controlled dispersion, i.e., distribution, of the carbon fibers.

Surface heating and dissipation of static electricity

Auf Grund aller Forschungs-Ergebnisse war es möglich ein Rechenprogramm zu entwickeln, mit dem man die Bedingungen für Spezialeinsätze bestimmen und Variationen kalkulieren kann.

Dimensional stability – lightweight construction

By using carbon fibers with controlled distribution in the carbon paper sheet, high stiffness values are achieved even with low-gram material. The exact dimensional stability gives the carbon fiber-paper composite a smooth processability together with other materials.

Sandwich construction – organic sheet

Further developments make it possible to produce carbon non-wovens from 100% recycled fibers on an industrial scale. A sandwich construction represents interesting alternatives to the organic sheets made from primary fibers.

Radiation protection

Microwave measurements showed that, with carbon fiber paper KOHPA®, a shielding effect and thus a shielding efficiency of 99.7% radiation reduction and thus a shielding attenuation of 25 dB could be achieved.

Furthermore, the current market’s discussion shows that the subject of “protection from electromagnetic radiation” is being given high priority Meanwhile, the dissipative paper is used in ecological house construction, as well as retrospectively as wallpaper in existing apartments.

Following the sustainability concept

The advantage of this system results from the even, flat electrical current distribution, dimensional stability, and other possible uses. If the paper is damaged by holes or tears, the current flow is not impaired, and the proportional distribution maintained. Moveover, sustainability is fulfilled through the use of recycled carbon and paper fibers.

European patent No. EP 2848734 B1

Paper structure and its production in the wet-process of carbon fibers

European patent No. EP 2770104 B1

Electrically conductive paper structure