October 2021

KOHPA® therm – the world’s thinnest and lightest surface heating

Through many years of research and industrial production of carbon fiber papers with different carbon contents, it was necessary to find a level of electrical reactions that enables the project to generate surface heating that does justice to practical conditions. Papers with different carbon contents showed differentiated electrical resistances. The overall investigations show that the electrical conductivity values vary due to the smallest changes in the carbon content. During the industrial production of carbon fiber paper, this phenomenon requires extremely precise metering and controlled carbon fiber dispersion.

Surface heating

In accordance with all research results, it was possible to develop a computer program with which the conditions for special operations can be determined and variations calculated. Only secondary carbon fibers are used. During electromobility, this paper will have a future, as the area-related heating output requires less electricity than those previously used.

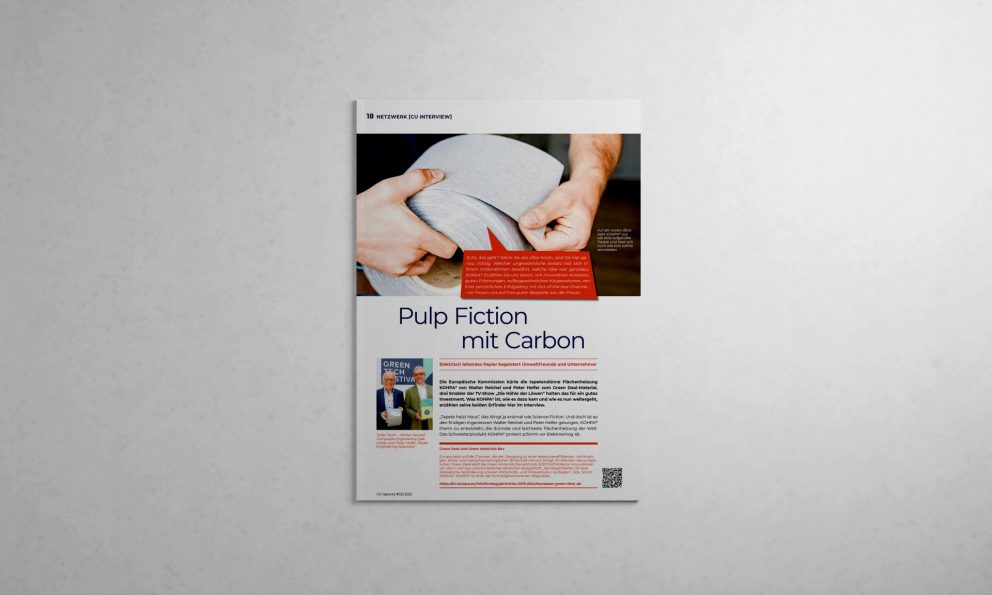

The thinnest and lightest surface heating made from electrically conductive paper

The novelty of this electrically conductive carbon paper, with a mass per unit area of only 80 g / m² and an extremely small thickness of 0.20-0.22 mm, represents the thinnest and lightest surface heating in buildings, but also in hard-to-reach places or within complex shapes. The practical implementation is characterized by the extremely small space requirement, the good formability and an absolute dimensional stability. The investment costs are low.

Compared to conventional heating systems, profitability is shown positively by the radiant heat achieved. Heating costs are reduced, which means energy saving. An electrical output of 150 W / m² is required for a temperature increase of 35 ° C. The carbon paper is compatible with its own photovoltaic system in combination with electricity storage, which enables an achievable, high degree of independence. Allergy sufferers have a positive health aspect in that there is minimal dust circulation within the room due to radiant heat, compared to conventional heating. The patented carbon fiber paper is used to combat mold growth, in which the dew-point is displaced by a separate temperature control between 16-18 ° C. The advantage of this system results from the uniform, extensive electrical current distribution, dimensional stability and possible uses such as: ceiling, wall and floor heating, caravan and mobile home floor heating, desk and table heating and much more. All within the low voltage range between 24 to 48 V. If the paper is damaged by holes or tears, the power supply is not impaired. Proportional distribution is maintained. The carbon paper can also be made waterproof. Wet deformation, different degrees of absorbency and targeted air permeability values can be set according to the relevant requirements. The material can be treated and processed like normal paper, but with absolute dimensional stability.

In accordance with sustainability concepts

Radiant heat, with a high radiation density (no convection heat), ensures that objects are evenly heated, provides a natural, feel-good climate (tiled stove effect). Higher economy due to lower surface temperatures (radiant heat 35 ° C) than with convection heat (radiator 55 ° C) is achieved. In addition, the concept of sustainability is fulfilled by way of secondary carbon fibers.

European patent No. EP 2848734 B1

Paper structure and its production in the wet-process from carbon fibers

European patent No. EP 2770104 B1

Electrically conductive paper structure