December 2021

The Discovery of Recycled Carbon Fibers

Carbon Fiber Reinforced Plastics (CFRP) are being increasingly used as industrial lightweight construction materials. This past growth trend will continue into the future.

But what happens to the waste?

The two paper makers, Walter Reichel from Mering and Peter Helfer from Dachau, also asked themselves this question.

After five years of developmental work and further training, they delved more and more into the characteristics of carbon fibers. Through intensive studies and further laboratory tests, they finally became familiar with their properties. Carbon fibers differ fundamentally from paper fibers in terms of their structure, charge, and surface properties. Nonetheless, the challenge was to manufacture a flat product from these elastic fibers using the wet-laid process (wet process engineering), while maintaining the quality of the carbon fibers. Distributing the thin carbon fibers, with a thickness of 7 µm, evenly in an aqueous suspension and orienting them during production turned out to be the greatest challenge during the project.

By thermo-chemical cleavage (pyrolysis) of the resin-bonded carbon fiber composite material CFRP, it is possible to expose carbon fibers without damage. In March 2012, a large-scale test was successfully carried out in the former pyrolysis plant in Burgau by the papermakers and the management of bifa (Bavarian Institute for Waste Management).

The further developed wet-laid process, based on scientific research, allows the carbon fiber paper KOHPA to be homogeneously distributed together with the paper fibers, even when using up to 96% of carbon fibers.

The new product is electrically conductive and temperatures of more than 70°C can be reached using harmless low voltages. The use as surface heating offers, for example, the advantage of saving energy with minimal requirements for space.

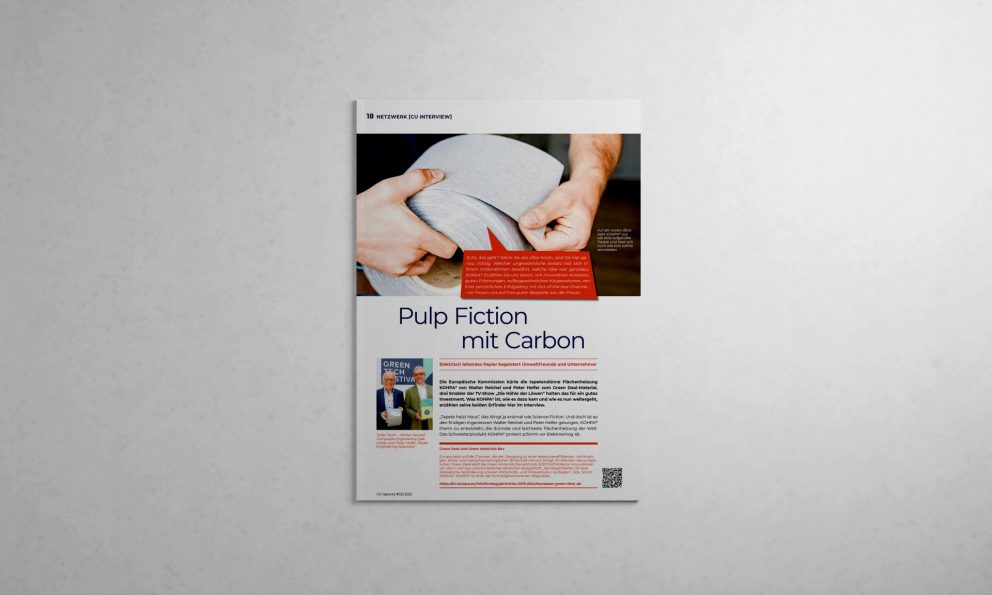

Another advantage, of the flexible carbon fiber material, is that the product retains its paper character, remains pliable and – like paper – can be molded and cut into shapes. Despite all this flexibility, the property of absolute dimensional stability under the influence of moisture is emphasized.

Laminating on stone, textiles or other materials is used in industry and processed in lightweight caravan construction. Among others, the carbon fiber paper can be used to shield against electromagnetic radiation, as a conductor against static electricity and can strengthen components.

Generally, it is customary to dry-process carbon fibers using textile technology. With the wet-process technology, a new, uncomplicated, and harmless production process is possible.

In addition, the concept of sustainability is fulfilled by way of recycled carbon and paper fibers.